WHITE PAPER: Role of Hybrid SF6 Switchgears Towards Sustainability

Download here.

Devraj Manna

Tamco Switchgears, Malaysia

Rupeshsingh Bess

Tamco Switchgears, Malaysia

Debangshu Ghosh

Tamco Switchgears, Malaysia

1. ABSTRACT:

Conventional GIS are generally bulky and having high SF6 content apart from high footprint. The other major concern is handling the SF6 gas at site. However, to avoid gas handling at site, Plugin Busbars were introduced, but the gas content

remained almost the same compared to the conventional GIS.

The advent of hybrid switchgear which is a combination of Gas Insulated Switchgear (GIS) and solid insulated screened busbars, resolved the issues faced by the utilities with existing conventional GIS. This requires zero SF6 in the busbar compartment. This came as a boon when the use of SF6 should be reduced as much as possible owing to its high global warming potential. Introduction of plug in type Voltage transformers and outer cone cable bushings that could also accommodate the current transformers provided benefit of accessibility and helped in reduction of size of SF6 filled tank (restricted to switching units only) thereby reduction of SF6 consumption to the tune of 30 to 50%.

With the changing times, a wave of modularity has brought a paradigm shift in the switchgear design and its installation. Sub-system Modularity (Circuit Breaker & Disconnecting switch modular design) is another aspect that will make the switchgear maintenance friendly & with extended life. Modular design approach allows the system to be operated and serviced independently without affecting the operation of other modules. This is significant from operation and maintenance point of view and would be the preferred industrial standard. It may also allow the opportunity to upgrade or enhance the rating (retrofitting) thereby offering greater flexibility for growth. In turn increasing the life span of the switchgear installation. This paper describes a medium voltage Hybrid SF6 switchgear which is modular in its construction and is future ready.

2. SUSTAINABILITY:

Sustainability is often describe as having three dimensions or pillars: environmental, economic, and social. Sustainability often focuses on countering major environmental problems, including climate change, loss of biodiversity, loss of ecosystem services, land degradation, and air and water pollution.

Sustainability is becoming increasingly important across all industries as companies strive to balance economic success with long-term values that take measures to support the effort against climate change and ensure social progress to the benefit of all stakeholders. This quest for sustainability has brought about the need for companies to evaluate and change the way they think about a wide range of activities, including how to manufacture their products, and how to optimize processes and their business models.

As the demand for electricity is rising across the globe mainly due to industrial and population growth, the role of switchgear in the power sector, especially in the transmission and distribution 2-7 sector, has become increasingly crucial over the years.

Hence the switchgear industry needs to move towards adopting sustainable industry practices with a focus on decarbonization, eco-design, high efficiency, and a sustainable supply chain. However, there are several impediments in the switchgear industry striving to adopt sustainable industry practices, including high initial costs and the complexity of switchgear installations. But at the same time, significant opportunities for innovation and development for switchgear OEMs exist along the way.

3. SWITCHGEAR BACKGROUND & TRANSITION FROM AIS TO GIS:

Traditionally, medium-voltage switchgear has been air insulated, meaning that the principal method for achieving dielectric stability rests on enough air gaps between phase conductors. While air insulated switchgear (AIS) has been the accepted solution, it is prone to the effects due to environmental conditions, more maintenance cost over a lifetime, cover more space and more installation time.

However, with time the electrical distribution technology has seen the transition from air insulated switchgear (AIS) to gas insulated switchgear (GIS). Gas insulated Switchgear (GIS) are preferred in restricted places, such as small spaces, these gadgets can be used in a very secure manner. It is used, for instance, in the expansion of city structures as well as on offshore platforms, roofing, and unrelated installations like hydropower and industrial.

Installing GIS may go more quickly than installing its AIS equivalent. This is mostly because GIS systems are substantially lighter and smaller. Low/zero maintenance is important given the entering workforce. With so many people just learning the equipment, less maintenance means less chance for human error. Reducing arc flash incidents is perhaps the greatest benefit of Gas insulated switchgear (GIS) technology.

GIS installations increases reliability of mediumvoltage switchgear, making it an easy choice for new installation and in upgrades. As the industry faces budget cuts, worker retention issues, and stricter guidelines, innovative solutions are needed. Gas insulated switchgears relieves budget concerns and constitutes a safe and reliable asset.

In a nutshell GIS have following advantages over AIS:

Compact Footprint: GIS occupies very less space compared to AIS.

Environmental Effect: GIS is very reliable under highly polluted, offshore, and saline environment.

High reliability & Less Vulnerable to Fault: LIVE parts being unaffected by environment, GIS is more reliable compared to AIS.

Minimal Maintenance: GIS has no exposed LIVE parts and doesn’t have withdrawable parts (e.g., VCB). MV-GIS are conceived as place-and-forget solutions.

Easy Installation: MV GIS installation is faster and quicker compared to AIS due to compact size and less moving parts.

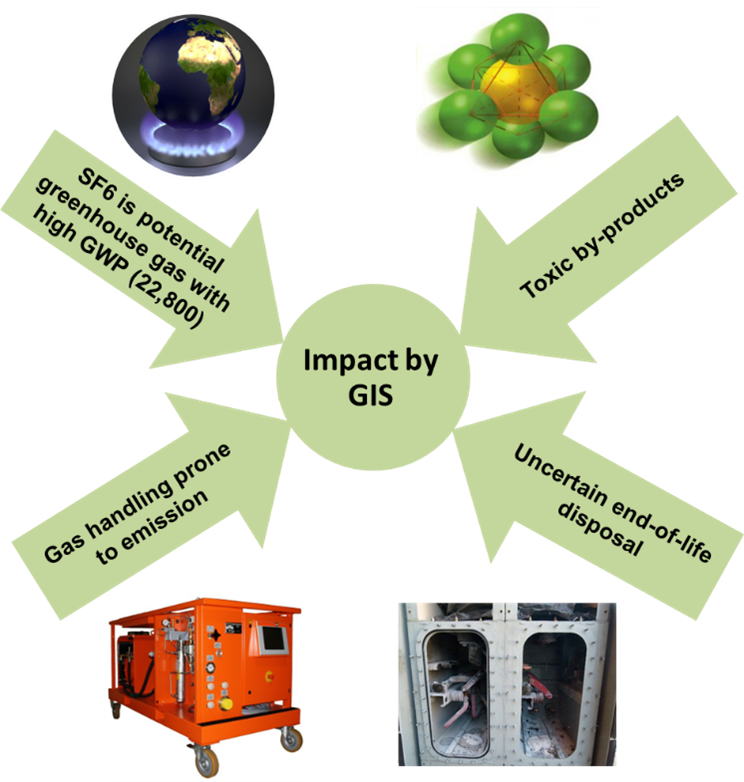

4. SWITCHGEAR BACKGROUND & TRANSITION FROM AIS TO GISENVIRONMENTAL IMPACT BY GAS INSULATED SWITCHGEAR’S:

Gas insulated systems are now a major component of power transmission and distribution networks all over the world, having all components interconnected and insulated via compressed SF6. Due to their compactness and metal shielding, they offer significant savings in land use, are aesthetically acceptable, have relatively low radio and audible noise emissions, and enable substations to be installed in cities very close to the loads. SF6 paved the way to space-saving equipment for the transmission and distribution of electrical energy.

Sulphur Hexafluoride (SF6) is an anthropogenically produced slow reacting gas with a relatively high molecular weight. It exhibits excellent arc extinction properties, and this gives rise to its high applicability in power technology. In its normal state it is chemically inert, non-toxic and non-flammable. Because of its inertness and nontoxic characteristics, it has been treated as an environmentally safe and acceptably non-toxic material, in the sense that it does not react unfavorably with the biomass.

Sulphur Hexafluoride (SF6) is an anthropogenically produced slow reacting gas with a relatively high molecular weight. It exhibits excellent arc extinction properties, and this gives rise to its high applicability in power technology. In its normal state it is chemically inert, non-toxic and non-flammable. Because of its inertness and nontoxic characteristics, it has been treated as an environmentally safe and acceptably non-toxic material, in the sense that it does not react unfavorably with the biomass.

However, when dissociated under high-pressure conditions in an electrical discharge the pure SF6 may readily reform toxic by-products. Its ever-rising usage in the electrical grid also played a decisive role in the continuous increase of atmospheric SF6 abundance over the last decades.Its ever-rising usage in the electrical grid also played a decisive role in the continuous increase of atmospheric SF6 abundance over the last decades.

It is a potent greenhouse gas with a high global warming potential, and its concentration in the earth atmosphere is rapidly increasing. Without appropriate disposal methods it can be expected that all the SF6 that has been or will be produced will eventually end up in the atmosphere. As a result, the concentration of SF6 in the earth atmosphere is increasing rapidly. These facts dictate new policies for safe gas handling requirements in the working environment and for component design (i.e., use of hermetically sealed equipment, exploitation of alternative gas mixtures etc.) to provide for personnel safety and long-term environmental protection

It should also be borne in mind that while these products are manufactured under controlled conditions in industrialized countries, they are being sold worldwide, including countries where controls embodied in the F-Gas Regulations and similar legislation are not enforced. End-of-life disposal becomes even more uncertain in these countries. The risks are exacerbated when used equipment containing SF6 gas is exported as waste to third-world countries where it may be dismantled by unqualified personnel.

5. GIS ROLE IN THE SHIFT TO RENEWABLE ENERGY:

Continuous governmental support and improved wind and solar PV competitiveness are all driving the expansion of renewable energy. Gas Insulated Switchgear has a vital role to play in the shift to renewables and is expected to experience significant growth in the coming years as new projects are commissioned. Renewable energy installations require more switchgear in the electricity grid, it takes more solar panels and wind turbines to produce the same electrical output as a single thermal power station. So, as renewable power generation grows, GIS population will also grow exponentially.

36kV GIS Installation – Wind Farm

6. ALTERNATIVE SOLUTIONS:

A. N2-SF6 gas mixture:

It does not represent a valid alternative for switchgear applications as it does still require an important amount of gas SF6 in the mix.

B. CO2 + O2 gas mixtures:

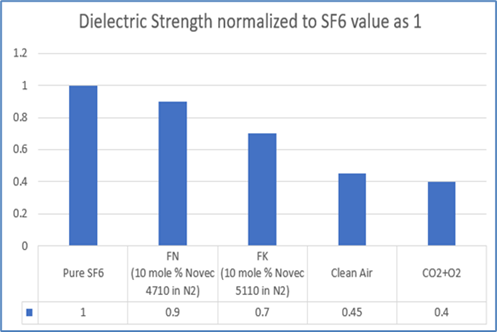

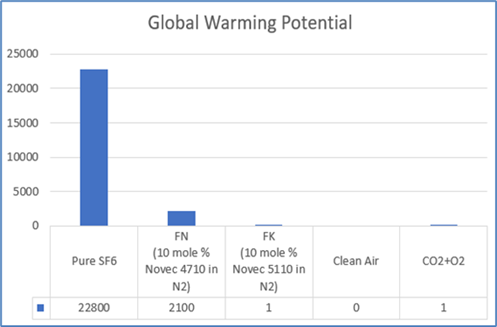

The gas mixture composition is typically 90% CO2 and 10% O2. It has a GWP (Global Warming Potential) of 1 since the GWP is based on the global warming potential of CO2, so it is 23,500 times better than SF6 from the environmental point of view. However, it is a much worse dielectric and it has worse arc-quenching capability than SF6.

C. Fluoronitriles gas mixtures:

The gas mixture composition (Novec 4710 fluid C4F7N + N2 / O2 / CO2) varies depending on the application and the switchgear manufacturer. The dielectric strength and interruption capability are still lower than SF6 (10 mole % of Novec 4710 in N2 is 0.9 times of SF6) and therefore it requires a higher operating pressure. The minimum working temperature is -25°C.

D. Fluoroketones gas mixtures:

The gas mixture composition (Novec 5110 fluid C5F10O +O2 + CO2) also varies depending on the application and the switchgear manufacturer. One problem of this gas mixture is its high temperature dew point which limits the minimum ambient working temperature (-5°C) at nominal operating pressures. As this gas mixture is an inferior dielectric and arc-quenching media than SF6 (10 mole % of Novec 5110 in N2 is 0.7 times of SF6), it is required to work at higher pressures and ambient temperatures which limits the application to indoor installations.

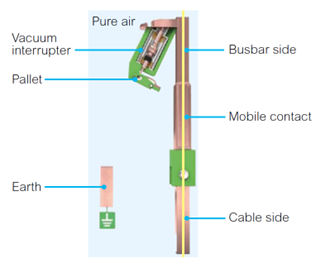

E. Clean Air with Vacuum Interrupter:

Clean Air or Dry Air has the same composition as the air in the atmosphere (Approx. 80% N2 + 20% O2) but without moisture and contamination. It has zero GWP. Clean Air is dielectrically significatively inferior to SF6 (Approx. 45% at the same pressure). Therefore, it requires higher pressure compared to SF6 switchgear. Clean Air is a poor arc interruption medium, so it is necessary to use a vacuum interrupter (VI) for interruption and Clean Air at high pressure for insulation.

Shunt Vacuum Interruption in Clean Air

Comparison of Dielectric strength

Comparison of GWP

7. CURRENT CHALLENGES FOR SF6 FREE TECHNOLOGY:

There are many ways that SF6 gas users can reduce or eliminate SF6 emissions. Training, proper SF6 gas handling procedures, and utilizing emission-free gas handling equipment greatly reduces the incidence of SF6 emissions. However, due to the GWP of SF6, a need for alternative solutions has been recognized in the industry. Advances in technology and years invested in R&D have allowed Original Equipment Manufacturers to start producing switchgear that operate with various alternatives to SF6 Gas.

The move away from SF6 switchgear is inevitable, but it will be a slow process with following challenges:

– Higher cost: SF6-free alternatives can be more expensive to produce than SF6-based circuit breakers. Utilities looking to make the switch to Alternatives to SF6 gas will have to make large investments to replace existing SF6 switchgear.

– Limited availability: SF6-free switchgears are still relatively new, and there are limited options available on the market.

– Transition strategy: Utilities are now facing the dilemma of how to best navigate through this transition to non- SF6 switchgear technology in the safest and optimum way. This conversion needs to be achieved whilst maintaining the reliability of the equipment by following optimized maintenance procedures gained with approx. 50 years of experience with SF6 circuit breakers and remaining flexible to future options in alternative gas technologies.

– Technology selection: Many non- SF6 options are currently available. There is no commonly agreed direction on which non- SF6 technology to pursue. Each manufacturer is choosing their own pathway without a congruent approach for the benefit of the end users. There is no unified international opinion on the best alternative. Every manufacturer has provided reasons as to why its solution is superior to others. It is not yet clear which will be the predominant media and when will it be universally adopted by industry.

– Field experience: Another consideration is that, due to the conservative nature of switchgear applications, utilities require references and proof of extensive field experience, not just laboratory certification, of the switchgear they install into the network. It is common practice amongst utilities that during the switchgear tender process a request is made for the supplier to provide a reference list of the places where the switchgear has been sold and some contact details of customers willing to provide feed-back of their experience. This represents a vicious circle; manufacturers need field experience by utilities to sell their new non-SF6 switchgear and utilities need a field proven non-SF6 switchgear to install in their network

Thus, HYBRID SF6 SWITCHGEAR’s provides a midway solution towards sustainability till the time above challenges are addressed.

8. TAMCO’s HYBRID SF6 SWITCHGEAR:

Hybrid switchgear is one that combines the components of traditional air-insulated switchgear (AIS) and SF6 gas-insulated switchgear (GIS) technologies. It is characterized by a compact and 6-7 modular design, which encompasses several different functions in one module.

Due to the introduction of Vacuum technology the need for withdraw ability has come under question. This is because withdraw ability was mandatory for maintaining the breaker operating mechanism and the power path of circuit breaker. However, with the continuous evolution of superior vacuum technology there is hardly anything which can or needed to be maintained in the power path. Thus, if nothing is to be maintained then why withdraw the circuit breaker at all. This resulted in a fixed breaker design with a disconnecting switch in series performing the isolating function.

Air insulated Fixed Type Switchgear remains compact upto 12kV range but at higher voltage level it is not possible to achieve compactness using air insulation. TAMCO has developed SF6 insulated hybrid switchgear that minimize the use of SF6 gas. TAMCO’s GV3N a 36kV Hybrid GIS Switchgear uses around 30-50% of SF6 gas in comparison to conventional 36kV GIS switchgear. This hybrid switchgear comprises of a vacuum interrupter housed inside a gas filled sealed tank. This modular approach is based on flexibility and customizability. The hybrid module can be used for extension or substitution in any traditional substation which uses an air-insulated busbar.

Hybrid GIS Switchgear Advantages:

Air Insulated busbar: The air insulated AIS busbar is relatively inexpensive while offering proven reliability. Screened busbars can be quickly and easily assembled at site. No SF6 handling making it environment friendly.

All live contacts in SF6: All switching units including the interconnecting conductors are insulated in SF6. The use of SF6 technology makes the hybrid switchgear virtually maintenance free, this combines with a high level of reliability to ensure a lower life cycle cost.

Factory pre-assembled and tested: The hybrid modules are fully pre-assembled and tested in the factory. This ensures a higher quality of finished bay than if it is assembled under site conditions, minimizes installation time on site. Reduces the possibility of delay due to adverse site conditions and there is less need for skilled resources on site.

Substation modularization: A modular approach to substation design offers cost and time savings during the design and construction phases. The use of standardized components reduces the number of possible variations and hence the risk of design errors. More predictable costs also offer a higher level of confidence in the project estimation process.

Space saving and reduced civil works: The hybrid design can save up to 50% of the space normally required for a conventional AIS substation, while also reducing the need for civil works such as foundations, steelwork, and cable trenching operations.

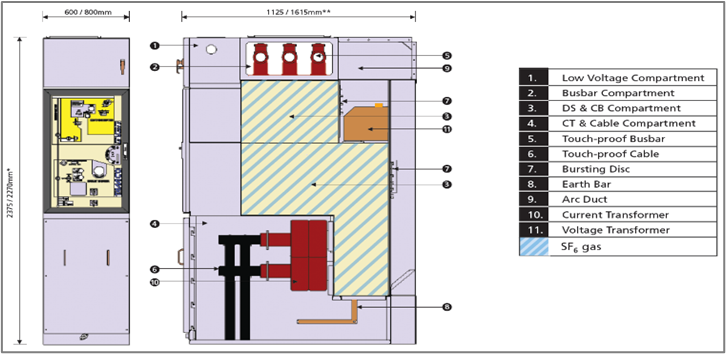

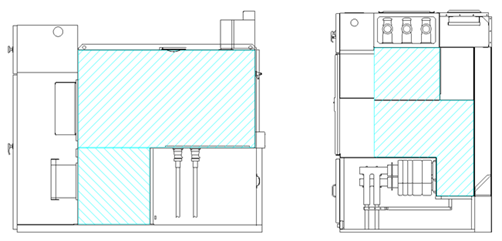

General arrangement for TAMCO’s 36kV GIS

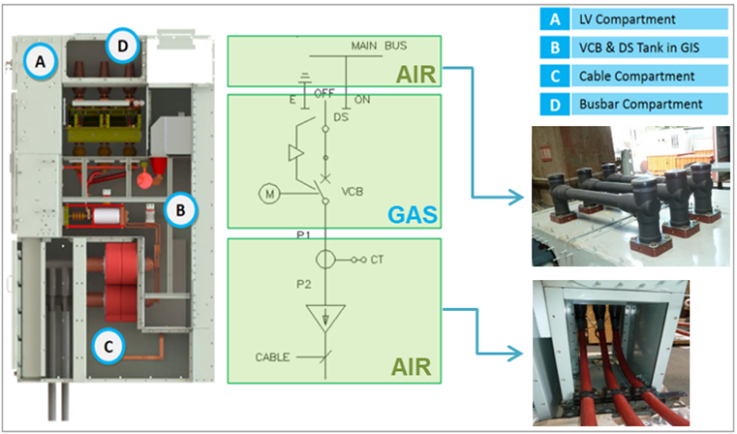

The TAMCO’s cubicle comprises 2/3 HV compartments & a control circuit compartment:

– Busbar compartment in air with Touch-proof (screened) busbars system.

– Cable compartment in air with Touch-proof (screened) cable termination system.

– VCB & DS compartment in SF6 gas.

– Low voltage compartment in air.

Typical construction & SLD for TAMCO’s 36kV GIS

The above approach requires minimal consumption of SF6 gas as only VCB & DS is only in SF6 gas unlike conventional GIS switchgear where all HV compartments are in SF6.

TAMCO’s conventional v/s Hybrid GIS (40-50% saving

in SF6 Gas consumption)

Features of TAMCO’s Hybrid GIS Technology:

– SF6 Gas Insulation with VCB for short circuit current interruption.

– Compact floor area, low carbon footprint.

– Min. maintenance, sealed for life contact system.

– Touch proof (screened) busbars in air.

– Ample cable termination height.

– Plug-in type cable termination, test facilities.

– Modular design with extension on both sides.

– Design for reliability with minimal maintenance.

9. Conclusion

GIS technology is proven, safest and most appropriate considering its compactness and reliability. Complete SF6 switchgears and complete non-SF6 switchgear has their limitations and till the time they are resolved Hybrid Switchgear is a midway Solution due to • its established and mature Technology • low consumption of SF6, thereby less greenhouse effect • carries all the advantages of conventional GIS.

Bibliography:

[2] “The impact of the application of vacuum switchgear at transmission voltages”. CIGRE Brochure #589, 2014, WG A3.27.

[3] Kyoto Protocol to the United Nations Framework Convention on Climate Change (1998) https://unfccc.int/kyoto_protocol.

[4] Challenges in the Transition to Non-SF6 High Voltage Switchgear in Australia and New Zealand:

A User’s Perspective (Cairns 2023 International Symposium).

[5] https://en.wikipedia.org/wiki/Global warming potential.

Related News

-

TAMCO Switchgear: Supporting Malaysia's Energy Transition

-

Switchgear – Standardize or Customize?

-

The Application of Switchgear in Data Centers

-

What is Switchgear? Understanding its applications in modern industries.

-

Makmal Pengujian Switchgear TAMCO Terima Sijil Pengiktirafan ISO 17025 - AWANI

-

WHITE PAPER: Role of Hybrid SF6 Switchgears Towards Sustainability

-

泰高开关设备测试实验室荣获ISO 17025认证

-

TAMCO Switchgear Testing Laboratory Receives ISO 17025 Certification

-

马来西亚TAMCO Switchgear 可持续发展与再生能源资源整合的先锋

-

Malaysia's TAMCO Switchgear at the Forefront of Sustainability and Renewable Energy Sources Integration